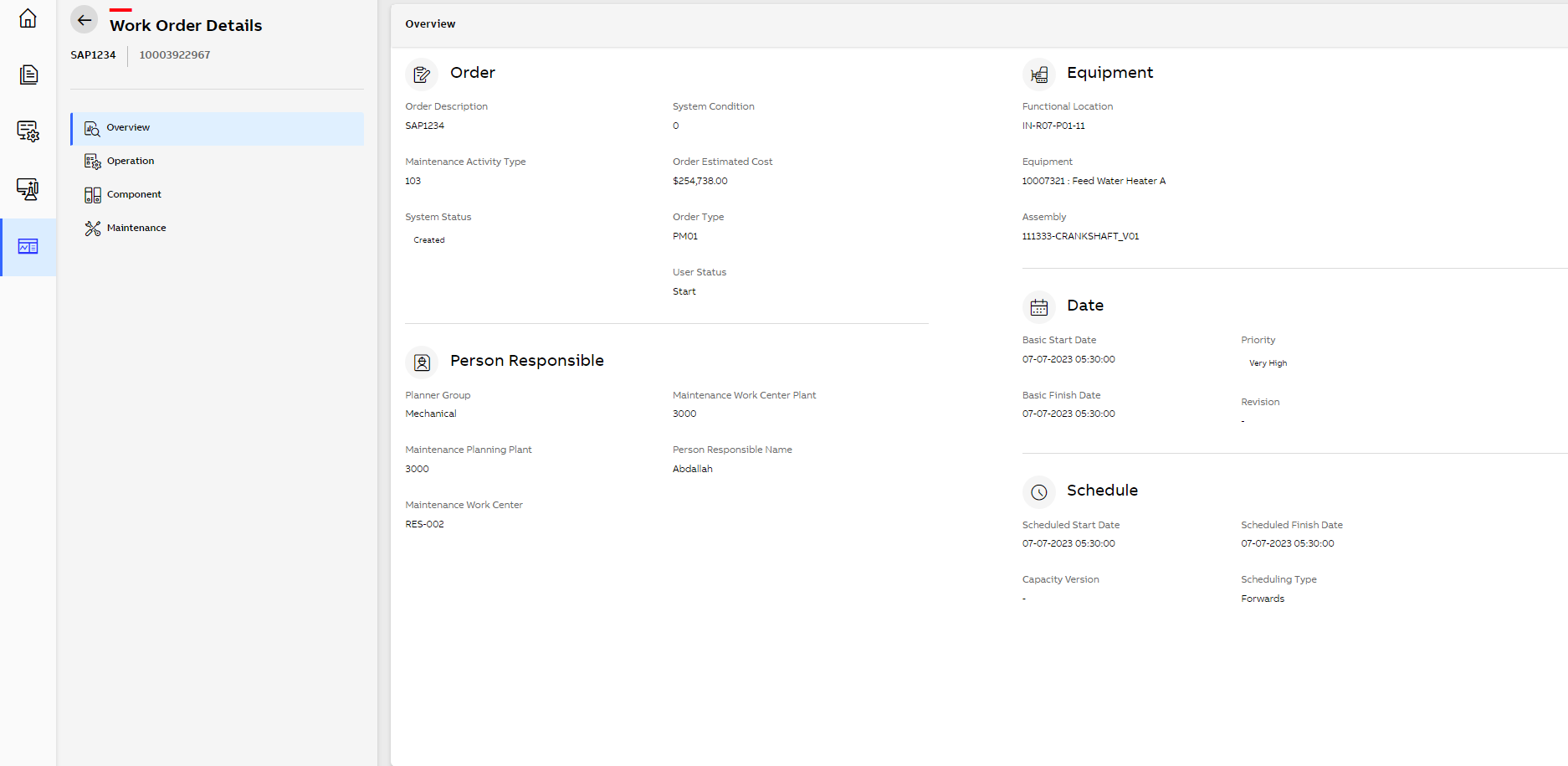

Overview

The Overview section under Work Order Details section provide detailed information about the following:

-

Order

-

Person Responsible

-

Equipment

-

Date

-

Schedule

Work Order Details - Overview

Order

The following table describes the fields under Order:

| Fields | Description |

|---|---|

| Order Description | Provides a brief description about the order created. |

| Maintenance Activity Type |

Displays the maintenance activity type. Activities are divided into repairs, shutdowns, regular activities, inspections and so on.

|

| System Status |

Displays the current status of an object. SAP System sets this status internally as a part of general status management. This status indicates the type of business transaction performed for an object. Following are the different types of System Status available:

|

| System Condition |

Displays the condition of an operational system. It indicates if the system must be operational or non operational state during execution. Following are the different types of System Status available:

|

| Order Estimated Cost | Displays the estimated cost of an order, which includes external material, external services, internal labor, internal material, or spares. |

| Order Type |

Displays or categorizes orders according to their purpose. The order type contains a range of parameters which affect the way the order is processed. For example, using the order type, you can specify the following:

You can select any one of the following maintenance order types under under Recommendation tab in Predictive Maintenance Workplace > Predictive Maintenance Workplace > Asset View:

|

|

User Status |

Displays the Field user status like EMRS -Scheduled in MRS (ext) , STOP - Stop , Strt - Start and so on. |

Person Responsible

The following table describes the fields under Person Responsible:

| Fields | Description |

|---|---|

| Planner Group |

Displays the planner group type in customer service or plant maintenance. A planner group is a group of employees responsible for planning and processing maintenance tasks in a plant. Following are the available planner group types:

|

|

Maintenance Planning Plant |

Displays planning plant number. Maintenance planning plants are standard plants indicated as maintenance planning plants during customization. Maintenance plants that do not plan their maintenance tasks are assigned to these planning plants. Planning is performed for the maintenance plants in the planning plants you enter. |

| Maintenance Work Center | Displays the work center that is in charge when a maintenance task is performed. |

| Maintenance Work Center Plant | Displays the plant in which the selected maintenance work center is located. |

| Personal Responsible Name | Displays the person's name who is responsible for the order or notification. |

Equipment

The following table describes the fields under Equipment:

| Fields | Description |

|---|---|

| Functional Location | Displays the functional location or place at which the maintenance task is performed. |

| Equipment | Displays the number by which a piece of equipment can be clearly identified. |

| Assembly |

Displays the assembly type of the equipment. Assembly separate technical objects into more clearly defined units in plant maintenance. For example, an automobile can be a technical object with the engine, gearbox, and chassis being the maintenance assemblies. |

Date

The following table describes the fields under Date:

| Fields | Description |

|---|---|

| Basic Start Date | Displays the date on which the work order is created. |

| Basic Finish Date | Displays the date on which the work order is completed. |

| Priority | Displays the importance of processing a specific order or notification. |

|

Revision |

Displays the Revision type or number for a specific work order. Revision allows grouping of Work Orders that are to be executed in a certain time period. For example, an upcoming downtime in which you want to execute a number of Work Orders. |

Schedule

The following table describes the fields under Schedule:

| Fields | Description |

|---|---|

| Scheduled Start Date |

Displays the Scheduled Start Date when the work for a specific work order is started. The Scheduled Start Date, also called the Planned Start Date, is the planned beginning of work on an assignment. |

| Scheduled Finish Date |

Displays the Scheduled Finish Date when the work for a specific work order is completed. The Scheduled Finish Date, also called the Planned End Date, is the planned completion of work on an assignment. |

| Capacity Version |

Displays the available capacity type for a specific particular work order. Following are the different types of Capacity Version available:

|

| Scheduling Type |

Displays the Scheduling Type for a specific work order. In order processing and control, the scheduling function calculates the production dates and capacity requirements for all operations within an order or a collective order. Following are the different types of Scheduling Type available:

|